An accessory guide for your rotary valves

Shear Protector

The shear protector is used for more granular materials such as plastic pellets, plastic flakes, wood pellets and larger, bulkier pieces of material.

It comprises of a mild-steel plate that sits on the valve's inlet port. It includes a bent wiper blade, with a flexible polyurethane tip. Its function is to prevent rotor jamming by stopping materials from getting pinched within the clearances of the rotor and housing. As material enters the rotor pockets through the inlet port, the shear protector's wiper blade sweeps any overflow granules into the next pocket, preventing jams.

Air Purge connect seal

The shaft seal purge is used to keep material away from the shaft seal which prolongs its life. This is important when you're conveying fine powders that are small enough to build up on the shaft seal and put you at risk of contamination or a combustible dust explosion. The air purge keeps your shaft seal clean, and keeps your machinery working

Zero Speed Switch

Industry 4.0 is here, which is why a zero-speed switch comes in handy for monitoring your valve. It lets your PLC system know when your shaft stops rotating, and will send an alarm out to prevent issues down the line.

Seal Types

There are more options than packing gland for your rotary valves, but we won't go into detail here.

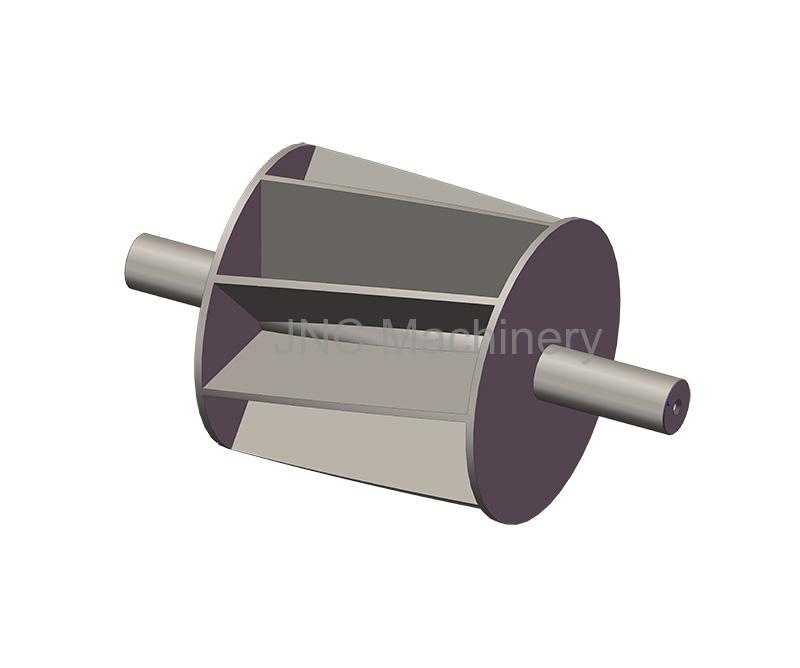

Rotor Types

Depending on your material type, it's a good idea to look at different rotor types that can treat your product with the most respect. For example, if you're looking for more uniform output, the Staggered Pocket Rotor might be for you. We have a breakdown of different rotor types .

- Prev: How to deal with rotary valve wear

- Next: No

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com

Mobile