Guide to valve rotor types

Here's our breakdown of each kind of rotor and how it works, to give you a better idea of what could work best for your application.

A closed end rotor has a disc attached to the rotor blades, ultimately preventing the blades from touching the endplates. There is a gap between the disc and the endplates that allows any material that does end up outside of the rotor to fall out the bottom easily.

Compared to closed end, open end rotors are generally easier to clean and maintain, which could ultimately lead to less material build up and wear on your valve. They are also better suited to mechanical seal applications.

Metering rotors are small precision rotors for extremely controlled flow. They are used when smaller amounts or test batches of material are needed.

Staggered pocket rotors have 16 offset pockets. They are recommended where more uniform flow is needed. With regular rotors, there are short breaks between when the material moves through the system as the rotor moves on its axis. Staggered pocket rotors allow for a continuous and smooth movement of the material into the system.

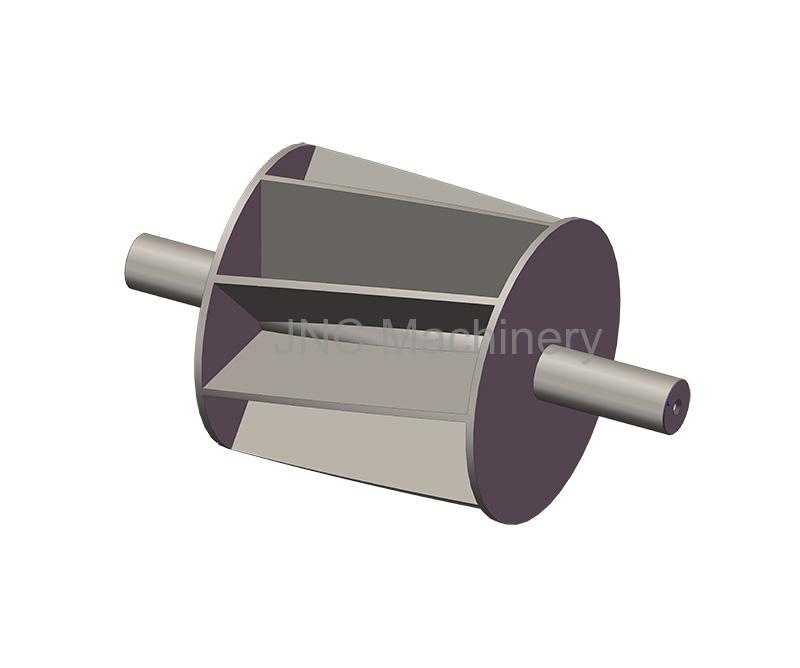

Reduced Volume Rotor

Another type of metering rotor, reduced volume rotors reduce the Cubic meter per Revolution (CFR) inside the valve. If a system has too much material moving into it, or the material flows too easily through the system, it could choke up the line beyond the valve. With reduced volume, it’s easier to control the flow.

The helical rotor is meant to act as a knife if any material gets caught between the rotor and the housing, to prevent any jams in the valve. Generally used for wood chips, if the material is going to get stuck, the rotor will cut it and continue to move.

Adjustable Rotor

With very harsh and abrasive material, tips will wear prematurely. With this type of valve, you can adjust the tips by sliding them up as they wear to keep them compliant and keep the clearance as close to their starting point as possible. This ultimately helps your valves last longer.

This rotor's pockets are U-shaped. The pocket shape minimizes material packing in the crease of a rotor vane, making it optimal for sanitary or food grade valves.

Material makes the difference

- Prev: How to deal with rotary valve wear

- Next: No

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com

Mobile