How to deal with rotary valve wear

One of the big issues in pneumatic conveying systems is wear life on rotary valves. Rotary airlock valves are the workhorse of the pneumatic conveying industry because they are usually the best device out there for metering material while creating a seal to differential pressure.

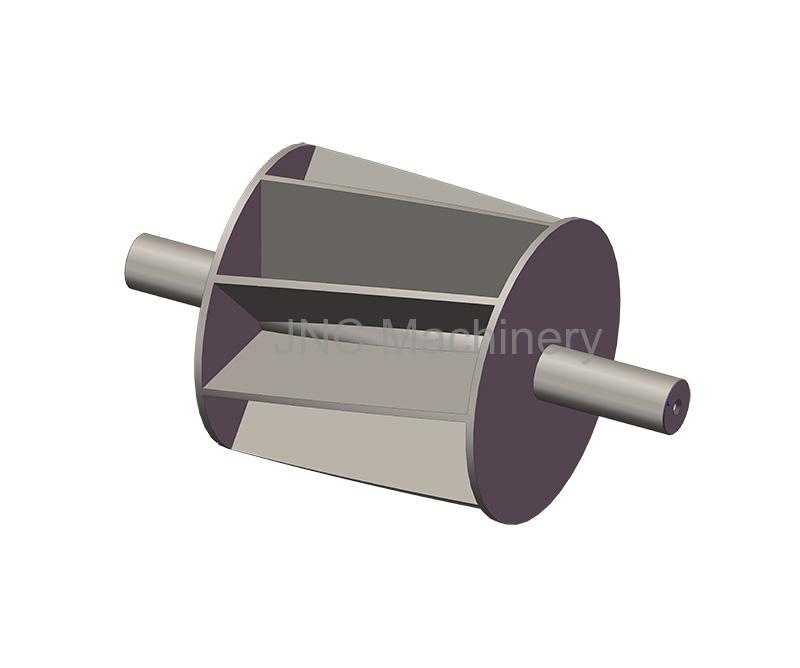

Their performance comes with a drawback, though. It is based on maintaining tight clearances that can erode over time. We get customer calls all the time asking how to check for wear, and if they can check the tolerances. Technically yes you can with a pair of feeler gauges but I would caution letting that be your deciding factor on needing to replace your valve or not. Rotary valves don’t wear out evenly, some wear out on one side and not the other (see image above); it all depends on the material being handled and the application conditions.

SO WHAT CAN BE DONE ABOUT ROTARY VALVE WEAR?

At JNC we provide configurations with chrome, or ceramic on the housing and end plates and hardened steel or tungsten carbide coated tips. These features can prolong life of the rotary valve by several hundred percent in different applications when compared to more basic valves. Additionally Cavity Air Purge and Shaft Air Purge also protect the rotary valve from wear.

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com

Mobile