Why we prefer direct drive instead of chain drive?

Let's break down why we think direct drive drive offer more advantages for your application.

Easy speed changes

Chain drive motors can provide easy speed changes, but direct drive can do it better.

A variable speed drive/variable frequency drive (VSD/VFD) on the direct drive motor allows speed to be increased or decreased at the turn of a dial. This also means less power is being wasted in higher rotations per minute (rpm), and less friction in the chain assembly, leading to increased efficiencies.

Real safety overload protection

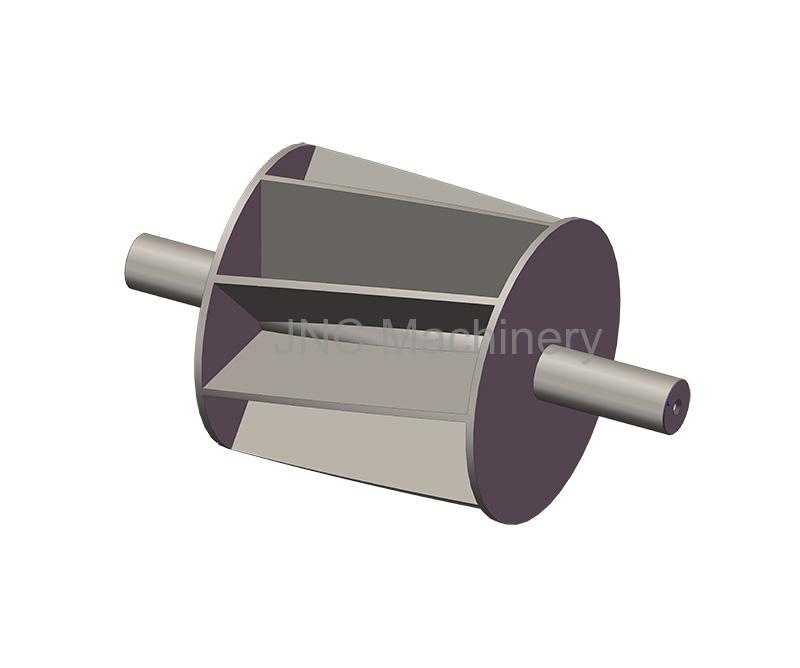

Chain drives are side mounted to the rotor, driving it through a chain and sprocket. Using chain drives can lead to increased maintenance and downtime if the chain were to break or elongate, which also means more safety risks for your plant workers.

In direct drives, having fewer parts also means having fewer parts prone to failure. Direct drives also have an overall longer lifetime and increased safety. Because direct drives are mounted on to the rotor shaft, you can give feedback to a sensor that is directly on a rotor part. This will give your application more precision, fewer pinch points and fewer safety hazards.

Chain drives, on the other hand, need more accurate mounting and careful maintenance to run effectively and efficiently. When they have been installed, they need regular maintenance and inspections on the chain to tighten it or ensure that it has proper lubrication.

In the food manufacturing industry, lubrication is an added risk of contamination, which can also put your products at risk of being recalled.

Both types of motors should include reduction gearboxes. Direct drives, however, can put out higher torque at a lower rpm due to the power savings from having no chain friction. The absence of a chain also means there are fewer parts that can vibrate, and much less noise.

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com

Mobile