Application and procurement of rotary airlock valve

Rotary airlock valve, with the valve driven by compressed air, when the gate valve is closed, the sealing surface can be sealed only by the medium pressure, that is, the sealing surface of the ram is pressed against the valve seat on the other side by the medium pressure to ensure the sealing of the sealing surface. This is self-sealing. Most of the gate valves are forced to seal, that is, when the valve is closed, the external force is forced to press the gate to the valve seat to ensure the sealing of the sealing surface.

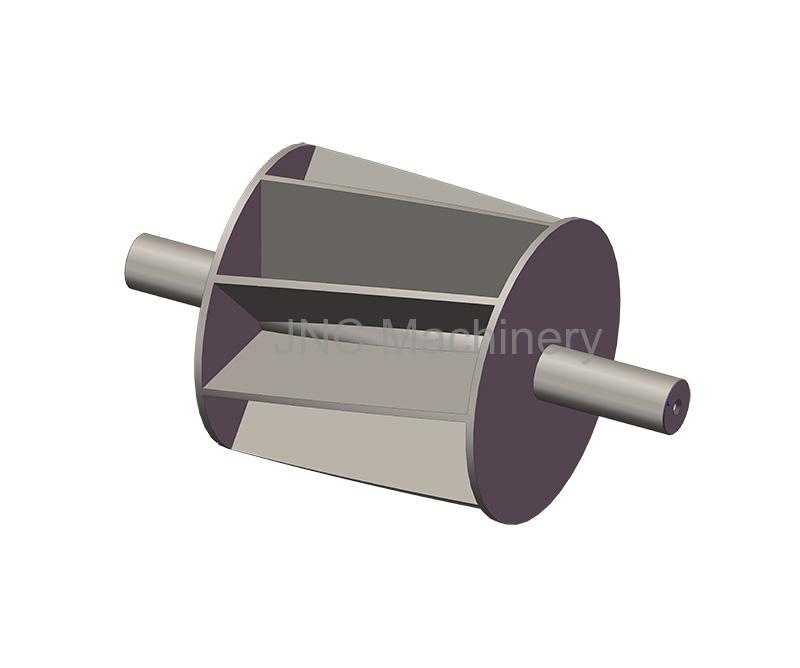

The rotary airlock valve is a right-angle rotary structure and is used with the valve positioner to achieve proportional adjustment. The V-type spool is most suitable for various adjustment occasions. It has a large rated flow coefficient and a large adjustable ratio. The effect is good, the adjustment performance is zero sensitivity, the volume is small, and it can be installed in a vertical position. Suitable for controlling gases, vapors, liquids and other media.

In the procurement, the rotary airlock valve purchase only clear specifications, categories, and work pressure to meet the procurement requirements, which is not perfect in the current market economy environment. Because the rotary airlock valve manufacturers compete for the products, each of them under the concept of unified design of the rotary airlock valve, to carry out different innovations, forming their own corporate standards and product personality. Therefore, in the procurement of pneumatic valves, the technical requirements are more detailed, and it is necessary to coordinate with the manufacturers to obtain a consensus, which is necessary as an attachment to the rotary airlock valve procurement contract.

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com

Mobile