Basic Application of fast clean rotary valve

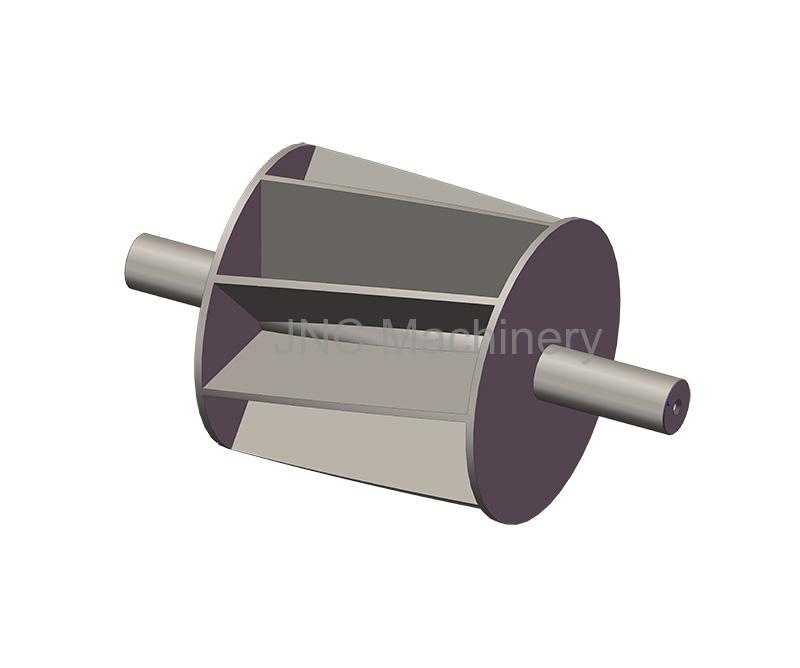

What is called a fast clean rotary valve? Fast clean rotary valve is a new type of rotary valve which is improved by adding cleaning blade on the basis of ordinary rotary valve. The device has the function of self-cleaning, and it can automatically remove the material on the rotor while feeding quantitatively. Fast clean rotary valve is especially suitable for special materials which are sticky and easy to cake. Every 1/6 turn, the scraper pulls any stuck material out of the bottom of the pocket, drops it out of the valve, and enters the process. This special unit is designed for oily sunflower shells, but it can be used for any product that accumulates viscous residues in the rotor.

The upper rotary valve is equipped with two upper and lower rotors, and the upper rotors are equipped with 5, 8 or 10 blades for the charging of the rotary valve; the lower rotors are equipped with cleaning blades for materials between the upper rotors ‘blades. Clean. When the equipment starts, the motor reducer drives the upper and lower rotors to start rotating at the same time. By using different rotational speeds of the upper and lower rotors, self-cleaning of the equipment during dosing is realized.Fast clean rotary valvecan be used in environments with certain temperature, pressure and explosion-proof requirements.

- No.7, Jinqiu Road, Qinxiang Village, Lijia Town, Wujin District, Changzhou City

- 0086-18015812727

- info@jncvalve.com

Mobile